X-band Solid State Transmitter Monitor User's Guide (TN-008)

This article describes the transmitter monitor board developed at CSU-CHILL. This board is designed for use in the Solid-state X-band project (WiBEX). The board monitors the operating conditions of the solid-state transmitter, and reports these to a higher-level controller. It can also shut down the transmitter in the event of a fault. The board is fully programmable via a Modbus/RTU interface.

Introduction

The transmitter monitor board is a critical component in the WiBEX radar design. Its primary task is to monitor the operating conditions of the solid-state transmitter. Secondary functions include a split power supply (+/- 5V) for the X-band microwave switches used in the front end of the WiBEX radar, a Peltier cooler driver for the X-band LNAs and a microwave switch driver.

Block Diagram

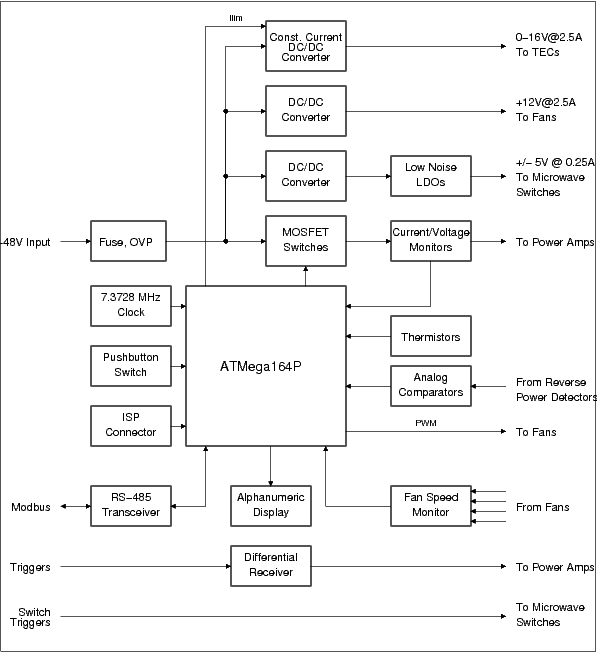

The figure below shows a block diagram of the board. The primary controller on the board is an Atmel ATMega164P microcontroller. This controller implements the main logic of the board, along with the Modbus/RTU slave logic. Various peripherals available on the microcontroller are used to interface to the analog electronics on the board.

Block Diagram

Components

Power Entry

Microcontroller

RS-485 Interface

Alphanumeric Display

Power Amplifier Supply

MOSFET Switch

Voltage Monitor

Current Monitor

Microwave Switch Supply

DC/DC Converters

LDOs

Fan Power Supply

TEC Power Supply

Thermistors

Fan Monitor

Modbus Registers

The interface to the synthesizer is through Modbus/RTU. The Modbus communications model is a single master controlling various slave devices[1]. Each slave is addressable, and has different registers which may be read or written. This design implements read-only registers (referred to as Input Registers in the Modbus specifications) and read-write registers (Holding Registers). There are no coils or status bits available.

Input Registers

The available input registers are shown in the table below:

| Register Number | Name | Description |

|---|---|---|

| 1000 | ALARM | Indicates the cause of any alarms indicated by the Modbus ALM signal. Reading the register clears the alarm condition and deasserts the Modbus ALM signal. |

| 1001 | STATUS | Indicates the operating status of the transmitter. |

| 1002 | TEMP_AMP1 | Amplifier 1 temperature, in degrees C multiplied by 100. |

| 1003 | TEMP_AMP2 | Amplifier 2 temperature, in degrees C multiplied by 100. |

| 1004 | FAN1_RPM | Power Amplifier cooling fan 1-4 speed, in revolutions per minute. |

| 1005 | FAN2_RPM | |

| 1006 | FAN3_RPM | |

| 1007 | FAN4_RPM | |

| 1008 | V_AMP1 | Amplifier 1 voltage, in millivolts. |

| 1009 | I_AMP1 | Amplifier 1 current, in milliamperes multiplied by 10. |

| 1010 | V_AMP1 | Amplifier 2 voltage, in millivolts. |

| 1011 | I_AMP1 | Amplifier 2 current, in milliamperes multiplied by 10. |

| 1012 | TEMP_HOT | Peltier cooler hot-side (heatsink) temperature, in degrees centigrade multiplied by 100. |

| 1013 | TEMP_COLD | Peltier cooler cold-side (LNA) temperature, in degrees centigrade multiplied by 100. |

| 1014 | PFAN_RPM | Peltier cooler heatsink fan speed, in revolutions per minute. |

| 1015 | RP_COUNT | Reverse power pulses per second. |

Input Register Map

Alarm Register

This register contains bit values that may be used to determine the cause of an alarm/fault. The bits are described below.

| Bit | Name | Description |

|---|---|---|

| 7 | Peltier Overtemp | A Peltier Overtemperature event is declared when the Peltier cooler hot-side temperature (TEMP_HOT) exceeds the limit programmed in PELTIER_TEMP_HIGH. |

| 6 | Fan Failure | A Fan Failure event is declared when more than two power amplifier blowers fails. A fan failure is defined as the fan rotation speed falling below 1000 rpm. |

| 5 | Reverse Power | A Reverse Power event is declared when the reverse power detectors detect more than the number of reverse power events specified in RP_COUNT_LIMIT per second. |

| 4 | Power Amplifier Overtemp | A Power Amplifier overtemperature event occurs when either power amplifier base plate temperature exceeds PA_TEMP_HIGH. |

| 3 | Reserved | |

| 2 | Reserved | |

| 1 | Overcurrent Fault | An overcurrent fault occurs when either PA draws more than PA_CURRENT_HIGH amperes. |

| 0 | Under/over Voltage Fault | An overvoltage fault occurs if the PA supply voltage falls outside the range bounded by PA_VOLT_LOW and PA_VOLT_HIGH |

ALARM register (address 1000)

Any fault will result in the appropriate bit being set in the ALARM register, the Modbus ALM signal being asserted, and the power amplifier power supply being shut off. Reading the alarm register clears the fault if the alarm condition no longer exists. For example, if an overtemperature event caused bit 4 to be set, but the amplifier temperature falls within the allowed window after the alarm event, reading the ALARM register will clear the fault. If the amplifier temperature is still too high, however, the fault does not get cleared.

Holding Registers

The available holding registers are shown in the table below:

| Register Number | Name | Description |

|---|---|---|

| 1000 | DISP_MODE | Mode of the alphanumeric display. |

| 1001 | PA_CONTROL | Power amplifier power control. |

| 1002 | FAN_MODE | Power amplifier cooling fan mode. |

| 1003 | FAN_TGTSPEED | Target speed of the power amplifier cooling fans when in manual mode. |

| 1004 | FAN_P_FACTOR | Proportional gain for the fan speed control loop, when in automatic mode. |

| 1005 | FAN_I_FACTOR | Integral gain for the fan speed control loop, when in automatic mode. |

| 1006 | FAN_D_FACTOR | Differential gain for the fan speed control loop, when in automatic mode. |

| 1007 | RP_COUNT_LIMIT | Number of reverse power pulses per second needed to trigger an alarm. |

| 1008 | PELTIER_TEMP_SETPOINT | Temperature that the Peliter cooler tries to attain, when in closed loop (automatic) mode. |

| 1009 | PELTIER_P_FACTOR | Proportional gain for the Peltier cooler control loop, when in automatic mode. |

| 1010 | PELTIER_I_FACTOR | Integral gain for the Peltier cooler control loop, when in automatic mode. |

| 1011 | PELTIER_D_FACTOR | Differential gain for the Peltier cooler control loop, when in automatic mode. |

| 1012 | PA_VOLT_LOW | Lower limit of the acceptable power supply input voltage range. |

| 1013 | PA_VOLT_HIGH | Higher limit of the acceptable power supply input voltage range. |

| 1014 | PA_CURRENT_HIGH | Upper limit of the current that may be drawn at the power amplifier contacts. |

| 1015 | PA_TEMP_HIGH | Maximum power amplifier temperature. |

| 1016 | PELTIER_TEMP_HIGH | Maximum Peltier hot-side temperature. |

| 1017 | FAN_SPEED_LOW | Minimum rotation speed before a fan failure is declared. |

Holding Register Map

Display Mode

The display mode register permits the mode of the onboard alphanumeric display to be changed. Supported display modes are shown below:

| Mode | Description |

|---|---|

| 0 | PA 1 Voltage |

| 1 | PA 1 Current |

| 3 | PA 2 Voltage |

| 4 | PA 2 Current |

| 5 | Peltier Cooler cold side temperature |

| 6 | Peltier Cooler hot side temperature |

| 7 | Amplifier 1 temperature |

| 8 | Amplifier 2 temperature |

| 9 | Fan 1 speed |

| 10 | Fan 2 speed |

| 11 | Fan 3 speed |

| 12 | Fan 4 speed |

| 13 | Peltier cooler fan speed |

Display Modes

It is not recommended to reprogram the display mode using Modbus, since the display is meant for local interaction with the board.

Fan Mode

The fan mode register selects the operating mode of the power amplifier cooling fans.

| Number | Mode | Description |

|---|---|---|

| 0 | Manual | The fan target speed specified in FAN_TGTSPEED is used to control the fans. |

| 1 | Automatic | The fan target speed is automatically determined to maintain the PA temperature specified in PA_TEMP_HIGH. |

Fan Modes

Fan Control Loop parameters

A PID controller is used to determine the fan speed in the automatic fan mode. The FAN_P_FACTOR, FAN_I_FACTOR and FAN_D_FACTOR are used to set the PID parameters. The parameters are internally divided by 128. There are no units assigned.

Peltier Temperature Control Loop parameters

A PID controller is used to determine the drive current to the Peltier cooler. The PELTIER_P_FACTOR, PELTIER_I_FACTOR and PELTIER_D_FACTOR are used to set the PID parameters. The parameters are internally divided by 128. There are no units assigned.

Connectors

Other Resources

References

- ↑ http://www.modbus.org/specs.php Modbus specifications