X-band Solid State Transmitter Monitor User's Guide (TN-008)

This article describes the transmitter monitor board developed at CSU-CHILL. This board is designed for use in the Solid-state X-band project (WiBEX). The board monitors the operating conditions of the solid-state transmitter, and reports these to a higher-level controller. It can also shut down the transmitter in the event of a fault. The board is fully programmable via a Modbus/RTU interface.

Introduction

The transmitter monitor board is a critical component in the WiBEX radar design. Its primary task is to monitor the operating conditions of the solid-state transmitter. Secondary functions include a split power supply (+/- 5V) for the X-band microwave switches used in the front end of the WiBEX radar, a Peltier cooler driver for the X-band LNAs and a microwave switch driver.

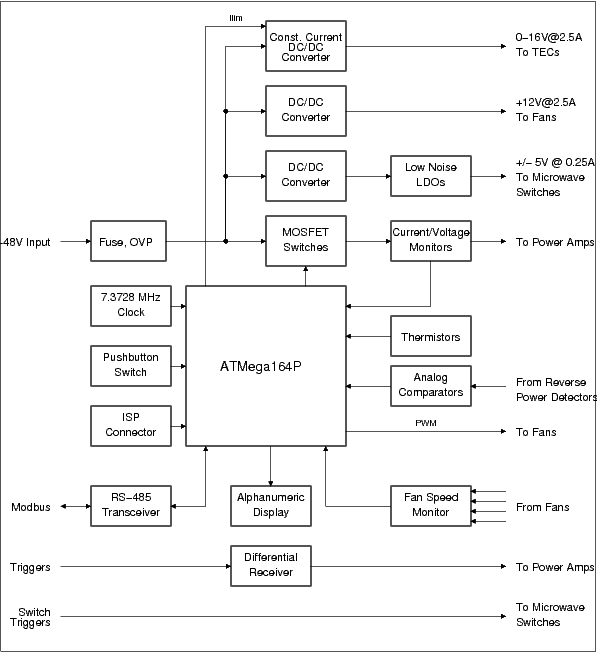

Block Diagram

The figure below shows a block diagram of the board. The primary controller on the board is an Atmel ATMega164P microcontroller. This controller implements the main logic of the board, along with the Modbus/RTU slave logic. Various peripherals available on the microcontroller are used to interface to the analog electronics on the board.

Block Diagram

Components

Power Entry

The 48V DC input voltage is passed through a power entry block, which has a 3.2A resettable fuse and a 68V transient suppressor. The transient suppressor also provides reverse voltage protection.

The board receives its power from a Lambda 48V, 6.3A AC/DC switch-mode power supply.

Microcontroller

This design uses an Atmel ATMega164P microcontroller, a low-power, low-cost 8-bit microcontroller. It includes 16 kB of Flash program memory, 1 kB of SRAM and 512 bytes of EEPROM. The onboard ADC is used to measure the PA voltage and current, as well as various temperatures. The SPI bus is used to communicate with the alphanumeric display. The I2C (two-wire) bus is used to communicate with the fan speed monitor.

I/O ports on the MCU are used to control the power MOSFETs that turn on and off the power to the amplifiers. On-board PWM generators are used to control the PA fan speed, as well as to generate a control voltage for the Peltier cooler supply. The analog comparator output and the Peltier cooler hot-side fan rotation signal are also read in through the I/O ports, where they are used to trigger CPU interrupt. A push-button switch is also read in through an I/O port. The switch is used to control the mode on the alphanumeric display, as well as a manual fault-reset input.

The UART is used to implement a Modbus/RTU interface through an RS-485 line interface. The MCU is clocked by a 7.3728 MHz crystal oscillator. The frequency is chosen to be a multiple of popular serial port baud rates such as 9600 bps. This permits the MCU to divide down the oscillator frequency to the baud rate with a very small error.

RS-485 Interface

The RS-485 line interface is provided using a MAX3088 driver/receiver. A common-mode choke is used to prevent high-frequency common-mode noise from affecting the MAX3088. The RS-485 A&B lines are protected from static discharge and accidental overvoltage conditions using a pair of 6.8V transient suppressors.

A baud rate of 57600 is used, with 8 data bits, Even parity and 1 stop bit (8E1).

Alphanumeric Display

The board includes an Avago HCMS-2973 eight-character dot-matrix LED display. The display interfaces to the MCU through the SPI bus. It appears as a shift register, with each bit corresponding to a pixel on the display. The MCU driver code includes a character map to convert ASCII characters to their dot-matrix representations. The display indicates one of several user-selectable parameters that are monitored by the board.

DIP Switch

A mode selection DIP switch is provided, to permit various operating parameters of the board to be adjusted. This is summarized in the table below:

| Switch # | Function when ON |

|---|---|

| 1 | Run PA fans at full speed |

| 2 | Run PA fans at minimum speed |

| 3 | Faults don't cause PA power to be shut off |

| 4 | No function assigned |

DIP Switch settings

Power Amplifier Supply

The dual-channel solid-state X-band power amplifier requires a 48V DC supply, at ~1 A per channel. Each channel has a voltage and current monitor. The PA supply needs to be switched in order to shut down the amplifier in the event of a fault condition.

MOSFET Switch

The power switching is accomplished using a high-side MOSFET switch. The high-side switch is a P-channel 20P06, capable of handling 15A continuous drain current. A VN10LF N-channel device is used to drive the high-side switch through a level translation network.

Voltage Monitor

A voltage divider provides a scaled version of the output voltage, which is monitored by the ADC on board the MCU.

Current Monitor

An LT6100 high-side current monitor chip is used, in conjunction with a 0.05 ohm shunt resistor, to monitor the current flow to each amplifier channel. The LT6100 generates a voltage proportional to the current flow through the shunt, which is sensed by the ADC on board the MCU.

Microwave Switch Supply

An auxiliary function of the transmitter monitor is to provide power for a pair of microwave switches. These switches are used in the WiBEX radar design to sample the transmitter signal, and to inject a known noise signal at the receiver inputs. The switches require a noise-free +/- 5V regulated DC, this is accomplished by using a DC/DC converter, then smoothing the output using a low-noise LDO.

DC/DC Converter

A Lambda PXE DC/DC converter module is used to generate a +/- 5.5V DC voltage from the input +48V. The DC/DC converter TRIM input is used to offset the output voltage to 5.5V, in order to provide some headroom for the LDO. The DC/DC converter output is also used to power the logic on the board, including the MCU.

LDOs

Linear Technologies LT1963A and LT1964 LDOs are used to generate the +/-5V DC voltage from the output of the DC/DC converter. The LDOs are configured to have maximum ripple rejection, and also use a ferrite bead to reject the high-frequency switching noise from the switch-mode DC/DC converter.

Fan Power Supply

The various fans driven by the board are powered from a DC/DC converter designed around an LM2576HV switch-mode regulator. The converter is designed to generate 12V@2.5A. The output voltage may be trimmed using a trim-pot on the board. Each of the four blowers used to cool the PAs requires approx. 0.6A when running at full speed, and the Peltier cooler blower requires a further 0.1A.

TEC Power Supply

The Thermoelectric Cooler (TEC) or Peltier power supply is a switch-mode DC/DC converter designed using an LM2576HV. This converter is designed to generate a constant current output, whose current limit is programmable using a DC control voltage. In addition, the power supply also has a programmable maximum output voltage, and will switch between Constant Voltage (CV) and Constant Current (CC) modes as needed.

The feedback loop of a standard LM2576HV regulator is modified to include two op-amps, one for the current feedback loop, the other for the voltage feedback. The outputs of the op-amps is fed to the LM2576HV Feedback terminal through a pair of diodes, which selects the lower of the two voltages, providing the mode-switching function. The voltage loop uses a voltage divider with a trim-pot to divide down the output voltage, the trim-pot allows the CV-mode voltage level to be adjusted.

The current loop senses the voltage across a 0.05 ohm low-side sense resistor. This voltage is fed through a non-inverting summing amplifier, where it is summed with the current limit control signal. The gains of each of the inputs are trimmed such that when the control signal is set to 0V, the current loop sets the maximum current to ~2.5A. By increasing the control signal level, the current limit level is smoothly adjustable down to 0A. In this design, the control signal is driven by a filtered version of a pulse-width modulation (PWM) output from the MCU, permitting the Peltier cooler current to be adjusted by the MCU.

Thermistors

The MCU senses the temperature of the two PA modules and the hot and cold side of the Peltier cooler using thermistors. The thermistors are connected as one half of a voltage divider, with the MCU ADC measuring the output of the divider.

Fan Monitor

Fan speed monitoring for the PA cooling blowers is implemented using a MAX6651 fan controller chip. The controller part of the chip is not used, since the blowers used have a speed control PWM input. Each fan is connected to a monitoring input on the MAX6651, which has four input channels. The MCU I2C interface is used to read the registers on the MAX6651, and measure the rotation speed of the fans.

The Peltier Cooler fan speed is monitored directly by the MCU. The rotation monitor output of that fan is connected to an external interrupt line on the MCU, which counts the time interval between successive interrupts.

Modbus Registers

The interface to the board is through Modbus/RTU. The Modbus communications model is a single master controlling various slave devices[1]. Each slave is addressable, and has different registers which may be read or written. This design implements read-only registers (referred to as Input Registers in the Modbus specifications) and read-write registers (Holding Registers). There are no coils or status bits available.

Input Registers

The available input registers are shown in the table below:

| Register Number | Name | Description |

|---|---|---|

| 1000 | ALARM | Indicates the cause of any alarms indicated by the Modbus ALM signal. Reading the register clears the alarm condition and deasserts the Modbus ALM signal. |

| 1001 | STATUS | Indicates the operating status of the transmitter. |

| 1002 | TEMP_AMP1 | Amplifier 1 temperature, in degrees C multiplied by 100. |

| 1003 | TEMP_AMP2 | Amplifier 2 temperature, in degrees C multiplied by 100. |

| 1004 | FAN1_RPM | Power Amplifier cooling fan 1-4 speed, in revolutions per minute. |

| 1005 | FAN2_RPM | |

| 1006 | FAN3_RPM | |

| 1007 | FAN4_RPM | |

| 1008 | V_AMP1 | Amplifier 1 voltage, in millivolts. |

| 1009 | I_AMP1 | Amplifier 1 current, in milliamperes multiplied by 10. |

| 1010 | V_AMP1 | Amplifier 2 voltage, in millivolts. |

| 1011 | I_AMP1 | Amplifier 2 current, in milliamperes multiplied by 10. |

| 1012 | TEMP_HOT | Peltier cooler hot-side (heatsink) temperature, in degrees centigrade multiplied by 100. |

| 1013 | TEMP_COLD | Peltier cooler cold-side (LNA) temperature, in degrees centigrade multiplied by 100. |

| 1014 | PFAN_RPM | Peltier cooler heatsink fan speed, in revolutions per minute. |

| 1015 | RP_COUNT | Reverse power pulses per second. |

Input Register Map

Alarm Register

This register contains bit values that may be used to determine the cause of an alarm/fault. The bits are described below.

| Bit | Name | Description |

|---|---|---|

| 7 | Peltier Overtemp | A Peltier Overtemperature event is declared when the Peltier cooler hot-side temperature (TEMP_HOT) exceeds the limit programmed in PELTIER_TEMP_HIGH. |

| 6 | Fan Failure | A Fan Failure event is declared when more than two power amplifier blowers fails. A fan failure is defined as the fan rotation speed falling below 1000 rpm. |

| 5 | Reverse Power | A Reverse Power event is declared when the reverse power detectors detect more than the number of reverse power events specified in RP_COUNT_LIMIT per second. |

| 4 | Power Amplifier Overtemp | A Power Amplifier overtemperature event occurs when either power amplifier base plate temperature exceeds PA_TEMP_HIGH. |

| 3 | Reserved | |

| 2 | Reserved | |

| 1 | Overcurrent Fault | An overcurrent fault occurs when either PA draws more than PA_CURRENT_HIGH amperes. |

| 0 | Under/over Voltage Fault | An overvoltage fault occurs if the PA supply voltage falls outside the range bounded by PA_VOLT_LOW and PA_VOLT_HIGH |

ALARM register (address 1000)

Any fault will result in the appropriate bit being set in the ALARM register, the Modbus ALM signal being asserted, and the power amplifier power supply being shut off. Reading the alarm register clears the fault if the alarm condition no longer exists. For example, if an overtemperature event caused bit 4 to be set, but the amplifier temperature falls within the allowed window after the alarm event, reading the ALARM register will clear the fault. If the amplifier temperature is still too high, however, the fault does not get cleared.

Holding Registers

The available holding registers are shown in the table below:

| Register Number | Name | Description |

|---|---|---|

| 1000 | DISP_MODE | Mode of the alphanumeric display. |

| 1001 | PA_CONTROL | Power amplifier power control. |

| 1002 | FAN_MODE | Power amplifier cooling fan mode. |

| 1003 | FAN_TGTSPEED | Target speed of the power amplifier cooling fans when in manual mode. |

| 1004 | FAN_P_FACTOR | Proportional gain for the fan speed control loop, when in automatic mode. |

| 1005 | FAN_I_FACTOR | Integral gain for the fan speed control loop, when in automatic mode. |

| 1006 | FAN_D_FACTOR | Differential gain for the fan speed control loop, when in automatic mode. |

| 1007 | RP_COUNT_LIMIT | Number of reverse power pulses per second needed to trigger an alarm. |

| 1008 | PELTIER_TEMP_SETPOINT | Temperature that the Peliter cooler tries to attain, when in closed loop (automatic) mode. |

| 1009 | PELTIER_P_FACTOR | Proportional gain for the Peltier cooler control loop, when in automatic mode. |

| 1010 | PELTIER_I_FACTOR | Integral gain for the Peltier cooler control loop, when in automatic mode. |

| 1011 | PELTIER_D_FACTOR | Differential gain for the Peltier cooler control loop, when in automatic mode. |

| 1012 | PA_VOLT_LOW | Lower limit of the acceptable power supply input voltage range. |

| 1013 | PA_VOLT_HIGH | Higher limit of the acceptable power supply input voltage range. |

| 1014 | PA_CURRENT_HIGH | Upper limit of the current that may be drawn at the power amplifier contacts. |

| 1015 | PA_TEMP_HIGH | Maximum power amplifier temperature. |

| 1016 | PELTIER_TEMP_HIGH | Maximum Peltier hot-side temperature. |

| 1017 | FAN_SPEED_LOW | Minimum rotation speed before a fan failure is declared. |

Holding Register Map

Display Mode

The display mode register permits the mode of the onboard alphanumeric display to be changed. Supported display modes are shown below:

| Mode | Description |

|---|---|

| 0 | PA 1 Voltage |

| 1 | PA 1 Current |

| 3 | PA 2 Voltage |

| 4 | PA 2 Current |

| 5 | Peltier Cooler cold side temperature |

| 6 | Peltier Cooler hot side temperature |

| 7 | Amplifier 1 temperature |

| 8 | Amplifier 2 temperature |

| 9 | Fan 1 speed |

| 10 | Fan 2 speed |

| 11 | Fan 3 speed |

| 12 | Fan 4 speed |

| 13 | Peltier cooler fan speed |

Display Modes

It is not recommended to reprogram the display mode using Modbus, since the display is meant for local interaction with the board.

Fan Mode

The fan mode register selects the operating mode of the power amplifier cooling fans.

| Number | Mode | Description |

|---|---|---|

| 0 | Manual | The fan target speed specified in FAN_TGTSPEED is used to control the fans. |

| 1 | Automatic | The fan target speed is automatically determined to maintain the PA temperature specified in PA_TEMP_HIGH. |

Fan Modes

Fan Control Loop parameters

A PID controller is used to determine the fan speed in the automatic fan mode. The FAN_P_FACTOR, FAN_I_FACTOR and FAN_D_FACTOR are used to set the PID parameters. The parameters are internally divided by 128. There are no units assigned.

Peltier Temperature Control Loop parameters

A PID controller is used to determine the drive current to the Peltier cooler. The PELTIER_P_FACTOR, PELTIER_I_FACTOR and PELTIER_D_FACTOR are used to set the PID parameters. The parameters are internally divided by 128. There are no units assigned.

Connectors

| Refdes | Purpose | Type |

|---|---|---|

| J1 | Modbus I/O | 4p Terminal block |

| J2 | In-System Programming Port | 3x2 header |

| J3 | Power Input | 2p Terminal block |

| J4, J5 | PA Power | 2p Terminal block |

| J6 | PA Temp. | 4p MTA 100 |

| J7 | Peltier assembly | 2x4 Microfit-3.0 |

| J8, J10 | Switch drive | 2x3 Microfit-3.0 |

| J9 | PA trigger, switch trigger | 2x5 Microfit-3.0 |

| J11, J12, J13, J14 | Fan assemblies | 2x2 Microfit-3.0 |

| J15 | Power pass-though | 2p Terminal block |

| J16, J17 | Reverse power detectors | SMB vertical |

| J18 | PA drive | 2x3 Microfit-3.0 |

List of Connectors

Modbus I/O

This connector allows the synthesizer to connect to a Modbus/RTU bus. Also provides connection to the ALM (alarm) output. The "A" and "B" outputs are protected by a pair of transient suppressor diodes. Ferrite common-mode chokes are also provided for additional noise immunity.

Note that the silkscreened legend for the A and B terminals is reversed.

| Pin | Signal |

|---|---|

| 1 | B |

| 2 | A |

| 3 | GND |

| 4 | ALM |

J1 (Modbus I/O)

In-System Programming Port

This connector permits the ATmega164P Flash and EEPROM to be programmed during development. It is designed to mate to the Atmel AVRISP mkII programming cable.

| Pin | Signal |

|---|---|

| 1 | MISO |

| 2 | +5V |

| 3 | SCK |

| 4 | MOSI |

| 5 | RESET |

| 6 | GND |

J2 (In-System Programming Port)

Power Input, Power pass-though

+48V DC power for the transmitter monitor is applied at these connectors. A pass-through is provided for convenience in attaching other devices to the +48V line.

Any voltage over 68V or below -0.6V will cause an on-board Transient Suppressor Diode to switch on. If the board or any attached load draws over 3.2A of current, the resettable fuse will limit the current.

| Pin | Signal |

|---|---|

| 1 | +48V |

| 2 | GND |

J3, J15 (Power Input, Power pass-though)

PA Power

+48V DC power for the power amplifiers is available at these connectors. This is a switched version of the input +48V supply. The current and voltage at these terminals is monitored by the board.

| Pin | Signal |

|---|---|

| 1 | +48V |

| 2 | GND |

J4, J5 (PA Power)

PA Temperature

The thermistors used to monitor the power amplifier temperature are attached using this connector. Initially, the board was to use a Phoenix Contact miniature terminal block, but this was changed since the high-power microwave circulator blocks the wire entry if the terminal block is used. Instead, a non-polarized header compatible with the MTA100 series connectors is used.

| Pin | Signal |

|---|---|

| 1 | Amp. 1 thermistor |

| 2 | Amp. 1 thermistor return (GND) |

| 3 | Amp. 2 thermistor |

| 4 | Amp. 2 thermistor return (GND) |

J6 (PA Temperature)

Peltier assembly

This connector attaches the Peltier cooler assembly, used to regulate the temperature of the WiBEX radar LNAs.

| Pin | Signal |

|---|---|

| 1 | +12V |

| 2 | Hot side thermistor |

| 3 | Fan tachometer |

| 4 | Cold side thermistor |

| 5 | GND |

| 6 | Peltier negative |

| 7 | GND |

| 8 | Peltier positive |

J7 (Peltier)

Switch Drive

This connector attaches the microwave switches to the control board. The microwave switches derive their DC power as well as the switch drive signals.

| Pin | Signal |

|---|---|

| 1 | +5V |

| 2 | Drive (+) |

| 3 | -5V |

| 4 | Drive (-) |

| 5 | +5V (logic) |

| 6 | GND |

J8, J10 (Switch Drive)

PA trigger, switch trigger inputs

Drive signals for the power amplifier trigger (gate) and switch trigger are brought in from the timing generator on this connector.

| Pin | Signal |

|---|---|

| 1 | Trigger+, Channel 1 |

| 2 | Switch+, Channel 1 |

| 3 | Trigger-, Channel 1 |

| 4 | Switch-, Channel 1 |

| 5 | Trigger+, Channel 2 |

| 6 | Switch+, Channel 2 |

| 7 | Trigger-, Channel 2 |

| 8 | Switch-, Channel 2 |

| 9 | GND |

| 10 | GND |

J9 (PA trigger, switch trigger inputs)

PA Fan assemblies

Power amplifier blower fans obtain power and drive signals through these connectors. They also provide speed monitoring feedback to the control board.

| Pin | Signal |

|---|---|

| 1 | +12V |

| 2 | GND |

| 3 | Tachometer (feedback) |

| 4 | PWM speed control |

J11, J12, J13, J14 (Fan assemblies)

Reverse Power Detectors

These SMB connectors are used to attach the microwave power detectors used to determine if the reverse power at the antenna terminal is excessive.

| Pin | Signal |

|---|---|

| Center | Reverse Power signal |

| Shield | GND |

J16, J17 (Reverse Power Detectors)

PA Drive

This connector has the drive signals required by the two power amplifiers.

| Pin | Signal |

|---|---|

| 1 | Amp 1 Trigger |

| 2 | Amp 1 OK |

| 3 | Amp 2 Trigger |

| 4 | Amp 2 OK |

| 5 | GND |

| 6 | GND |

J18 (PA Drive)

Other Resources

References

- ↑ http://www.modbus.org/specs.php Modbus specifications